Imagine a world where vacuum pumps didn’t exist. From medical to industrial applications, these essential tools are behind countless processes we depend on daily. Whether you’re in science, manufacturing, or HVAC, understanding vacuum pumps is crucial for achieving optimal results. If you’re searching for the ideal pump for your specific needs, keep reading to explore the various types, considerations, and future trends in vacuum pump technology. This guide will walk you through the essentials of choosing the perfect vacuum pump for a wide range of applications.

Introduction to Vacuum Pumps

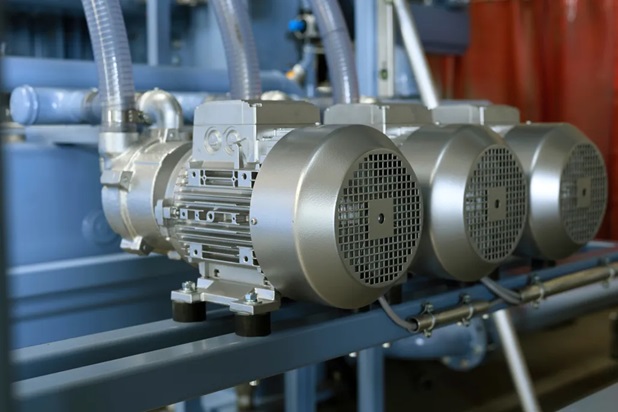

Vacuum pumps are devices that remove gas molecules from a sealed volume to create a partial vacuum. Their importance spans numerous industries, making them indispensable in processes ranging from semiconductor manufacturing to food packaging. Industrial vacuum pumps are used to create a controlled environment, essential for certain chemical reactions, sterilization processes, and even space simulations. Without vacuum pumps, many of our modern conveniences simply wouldn’t be possible.

In the medical field, vacuum pumps are critical for operations such as suctioning during surgery and maintaining sterile environments. In manufacturing, they play a role in creating products like light bulbs and electronics. Even in everyday life, vacuum pumps are in the background, helping to keep your refrigerator running efficiently. Understanding the correct pump for your application can enhance performance, reduce costs, and improve overall efficiency.

Types of Vacuum Pumps

Choosing the right vacuum pump starts with understanding the different types available. Vacuum pumps are generally classified into three main categories:

Positive Displacement Pumps

Positive displacement pumps work by mechanically trapping a volume of gas and then moving it through the pump. These pumps are highly effective for low to medium vacuum applications. Rotary vane pumps, one of the most common types, are found in everything from automotive applications to refrigeration systems. They are reliable, robust, and relatively easy to maintain, making them a popular choice for various industries.

Momentum Transfer Pumps

Momentum transfer pumps, also known as kinetic pumps, move gas molecules by imparting momentum to them. This type includes turbo molecular pumps and diffusion pumps. They operate in high-vacuum environments, such as those required for particle accelerators and vacuum coating processes. These pumps are ideal for applications needing ultra-clean conditions, as they offer minimal contamination.

Entrapment Pumps

Entrapment pumps capture gas molecules on surfaces within the pump. This category includes cryopumps and ion pumps, known for their ability to achieve extremely high vacuums. Entrapment pumps are commonly used in scientific research and semiconductor fabrication, where maintaining a pristine vacuum environment is essential. They are particularly suited for tasks requiring a low-maintenance solution, as they have no moving parts.

Factors to Consider When Choosing a Vacuum Pump

Selecting the right vacuum pump involves evaluating several critical factors that can significantly impact the efficiency and effectiveness of your operations.

Application

The first step in choosing a vacuum pump is understanding the specific requirements of your application. Different fields have unique needs, and selecting a pump that aligns with these can make a world of difference. In scientific laboratories, for example, precision and cleanliness might be top priorities, while in manufacturing, durability and efficiency could take precedence. Evaluate the gas type, volume, and operating pressure to ensure you choose a pump that meets your application’s demands.

Performance

Performance characteristics such as pumping speed, ultimate pressure, and gas ballast are vital when selecting a vacuum pump. Pumping speed determines how quickly a pump can remove air, while ultimate pressure is the lowest pressure a pump can achieve. Gas ballast helps prevent condensation of vapors within the pump. Matching these specifications to your application will optimize performance and ensure smooth operation.

Maintenance

Regular maintenance is crucial for the longevity and reliability of vacuum pumps. Consider the maintenance requirements of your chosen pump type. Positive displacement pumps might require more frequent oil changes, while entrapment pumps may need periodic regeneration. Choose a pump that aligns with your maintenance capabilities to prevent unnecessary downtime and extend the pump’s lifespan.

Cost and Efficiency

Balancing initial investment with operational costs is essential when selecting a vacuum pump. While some pumps may have a higher upfront cost, they could offer significant savings in terms of energy efficiency and maintenance. Energy-efficient models can reduce operating expenses over time, making them a cost-effective choice. Consider the total cost of ownership to ensure you’re making a financially sound decision.

Future of Vacuum Pump Technology

The world of vacuum pumps is evolving rapidly, driven by advancements in technology and changing industry needs. Emerging trends are paving the way for more efficient, sustainable, and versatile vacuum pump solutions.

Sustainable Solutions

Sustainability is a growing concern, leading to the development of eco-friendly vacuum pump technologies. Manufacturers are investing in pumps with reduced energy consumption and lower environmental impact. This trend is particularly crucial in industries where sustainability is a core value, such as renewable energy and clean manufacturing.

Advanced Materials

Innovations in materials science are enhancing the performance and durability of vacuum pumps. New materials offer improved resistance to wear, corrosion, and extreme temperatures. These advancements extend the lifespan of pumps, reducing maintenance costs and downtime. The use of advanced materials also enables pumps to operate more efficiently in challenging environments.

Conclusion

Selecting the appropriate vacuum pump is vital for efficiency, reliability, and cost-effectiveness. By understanding different types and considering factors like application and maintenance, you can make an informed choice. Staying updated on trends and innovations will keep you competitive and help optimize your operations.